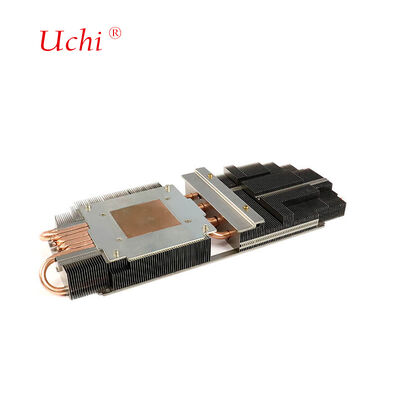

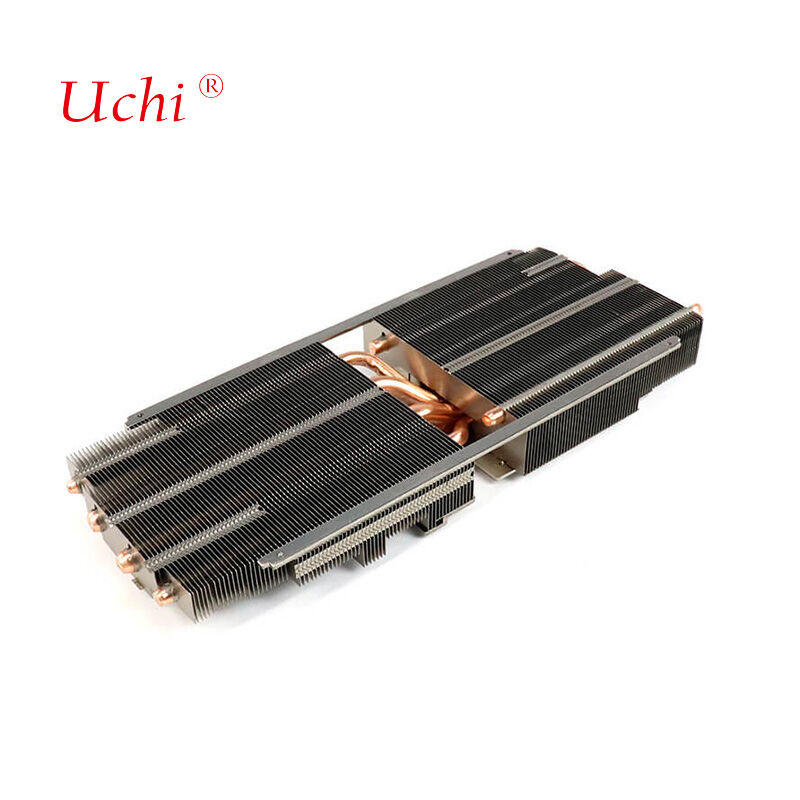

580W nhôm vây ống nhiệt Cpu tản nhiệt

Thông tin chi tiết sản phẩm:

| Nguồn gốc: | Đông Hoản, Quảng Đông, Trung Quốc |

| Hàng hiệu: | Uchi |

| Chứng nhận: | SMC |

| Số mô hình: | Tản nhiệt nhôm |

Thanh toán:

| Số lượng đặt hàng tối thiểu: | 100 chiếc |

|---|---|

| Giá bán: | có thể đàm phán |

| Điều khoản thanh toán: | T/T, paypal, Western Union, MoneyGram |

| Khả năng cung cấp: | 50000000 chiếc mỗi tháng |

|

Thông tin chi tiết |

|||

| Công suất dẫn nhiệt: | 580W | cuộc sống của người hâm mộ: | 50000 giờ |

|---|---|---|---|

| Vật liệu: | AL 1100 + CU 1020 | Kích cỡ: | 26,8 * 2,8 * 10,5cm |

| Cân nặng: | 0,718kg | Chứng nhận: | ISO9001:2015 ISO9001:14001 |

| Xử lý bề mặt: | dầu được làm sạch, làm sạch và thụ động | Tính năng: | Khả năng làm mát và độ dẫn điện cao |

| Làm nổi bật: | Máy thu nhiệt CPU nhôm 580W,Máy làm mát CPU ống nhiệt,tấm làm mát chất lỏng bằng vây nhôm |

||

Mô tả sản phẩm

580W nhôm vây ống nhiệt CPU tản nhiệt

Vật liệu:AL 1100 + CU 1020

Kích thước:26.8 × 2.8 × 10.5 cm

Công nghệ:Vòng kéo kéo

Xử lý bề mặt:Dầu lọc, làm sạch và thụ động

Khả năng dẫn nhiệt:580W

Máy thu nhiệt CPU hiệu suất cao này có công nghệ vây niêm phong tiên tiến, cung cấp khả năng làm mát đặc biệt và dẫn nhiệt cho các ứng dụng máy tính đòi hỏi.

Công nghệ vây trượt

Công nghệ vây trượt liên quan đến việc cắt cơ khí răng nhôm từ một hồ sơ để tạo ra các cấu trúc bộ tản nhiệt chính xác.được tối ưu hóa để làm mát thiết bị công suất cao trong điều kiện làm mát bằng không khíSo với các máy thu nhiệt thông thường, công nghệ vây trượt làm tăng hiệu quả phân tán nhiệt từ 8-15%.

Công nghệ bộ sưởi cánh trượt trưởng thành của chúng tôi có tính năng tự động hóa tiên tiến, cung cấp lợi thế chi phí và độ tin cậy đáng kể.Máy chuyển đổi tần số, bộ điều khiển, bộ chuyển đổi năng lượng gió, hệ thống SVG và đèn LED.

Các lĩnh vực ứng dụng

- Các mô-đun quang cắm 100G/200G cho các bộ chuyển mạch trung tâm dữ liệu

- Các mô-đun quang nhỏ cho thiết bị fronthaul/midhaul của trạm cơ sở 5G

- Các thành phần truyền thông quang năng lượng thấp cho các nút tính toán cạnh

Khả năng sản xuất

Công nghệ đồng hàn tiên tiến

CNC đồng / đồng

CNC nhôm / kẽm

Thép không gỉ / CNC thép

CNC nhựa

Các ứng dụng chính

Ánh sáng LED

Đèn đường LED công suất cao, đèn nhà máy, đèn sân khấu và đèn phát triển thực vật.kéo dài tuổi thọ của đèn và duy trì hiệu suất ánh sáng ổn định.

Điện tử điện

Các nguồn cung cấp điện cho máy chủ, các mô-đun điện liên lạc, hệ thống UPS, các bộ chuyển đổi tần số công nghiệp, trạm sạc xe điện và các biến tần quang điện.Các tản nhiệt được ép ra đảm bảo các thiết bị bán dẫn điện (IGBT), MOSFET) hoạt động trong phạm vi nhiệt độ an toàn, ngăn ngừa quá nóng và thất bại.

Kiểm soát và tự động hóa công nghiệp

Máy tính công nghiệp, bộ điều khiển logic có thể lập trình (PLC), ổ servo và bộ điều khiển robot.Máy thu nhiệt ép ra cung cấp sự phân tán nhiệt đáng tin cậy cho các thành phần điện tử nhạy cảm, đảm bảo hoạt động ổn định lâu dài.

Truyền thông

Các trạm cơ sở 5G, bộ định tuyến, chuyển mạch mạng và máy chủ trung tâm dữ liệu. Khi tốc độ truyền dữ liệu tăng lên, tản nhiệt cung cấp các giải pháp làm mát thụ động hiệu quả để giảm chi phí hoạt động.

Điện tử tiêu dùng

CPU / GPU làm mát máy tính để bàn hiệu suất cao, máy chơi game, hệ thống rạp chiếu phim gia đình và TV màn hình lớn.Máy thu nhiệt ép theo yêu cầu tối ưu hóa hiệu quả phân tán nhiệt và nâng cao trải nghiệm người dùng trong các thiết kế nhỏ gọn.

Xe năng lượng mới

Hệ thống quản lý pin điện (BMS), bộ điều khiển động cơ và bộ sạc trên xe.Các tản nhiệt được ép ra là các thành phần quan trọng đảm bảo hoạt động ổn định của hệ thống điện trong các điều kiện lái xe khác nhau.

Thiết bị sản xuất

Thiết bị làm mát bằng không khí của chúng tôi bao gồm: 10 đơn vị lò hàn nhiệt độ thấp, 5 đơn vị lò nướng, 20 đơn vị thiết bị hàn tự động,3 đơn vị thiết bị chải hàn tự động, 50 đơn vị vít máy điện điều khiển mô-men xoắn, 1 đơn vị thiết bị kiểm tra CCD, 2 đơn vị thiết bị kiểm tra mô-đun quang hoàn toàn tự động,11 đơn vị thiết bị thử nghiệm hiệu suất nhiệt đa trạm, 4 đơn vị thiết bị thử nghiệm quang học phẳng, và các thiết bị liên quan khác.

Cơ sở sản xuất tự động

Đảm bảo chất lượng

Chúng tôi duy trì các tiêu chuẩn chất lượng nghiêm ngặt với 1 Máy đo tọa độ, 1 thiết bị chiếu, 2 máy thử nghiệm nước áp suất cao, 4 máy thử nghiệm kháng nhiệt,và 2 máy kiểm tra rò rỉ chất lỏng.

Chứng nhận chất lượng

Dịch vụ khách hàng

- Trả lời nhanh chóng cho tất cả các yêu cầu

- Giá cạnh tranh với chất lượng đảm bảo

- Lịch sản xuất hiệu quả

- Giải pháp vận chuyển tối ưu

- Hỗ trợ kỹ thuật toàn diện

Câu hỏi thường gặp

Bạn là một công ty thương mại hay nhà sản xuất?

Chúng tôi là một nhà sản xuất chuyên nghiệp của thùng nhiệt và tấm làm mát nước với kinh nghiệm sâu rộng và một đội ngũ kỹ thuật mạnh mẽ, có tính năng sản xuất tự động và cơ khí.

Bạn đã xuất khẩu hàng hóa trước đây và đến những vùng nào chưa?

60% tổng sản lượng của chúng tôi được xuất khẩu sang Nhật Bản, Ấn Độ, Anh, Canada, Mỹ và Brazil.

Anh có bao nhiêu nhân viên?

Khoảng 100 nhân viên trên các phòng bán hàng, mua sắm, kỹ thuật, QA, kho và sản xuất.

Ông có thể cung cấp mẫu nếu chúng tôi đồng ý với thiết kế không?

Vâng, chúng tôi cung cấp mẫu để xác nhận trước khi sản xuất hàng loạt, cùng với bản vẽ kỹ thuật nếu cần thiết.

Các anh sử dụng phương pháp đóng gói nào?

Bao bì tùy chỉnh với các thùng carton thông thường và vải cứng hoặc thùng carton gỗ để bảo vệ tối ưu trong quá trình vận chuyển.

Bạn có cung cấp hỗ trợ kỹ thuật cho các vấn đề sản phẩm không?

Tất cả các sản phẩm được kiểm tra đầy đủ trước khi vận chuyển. Đối với bất kỳ vấn đề nào, chúng tôi cung cấp các giải pháp kỹ thuật ngay lập tức.

Muốn biết thêm chi tiết về sản phẩm này